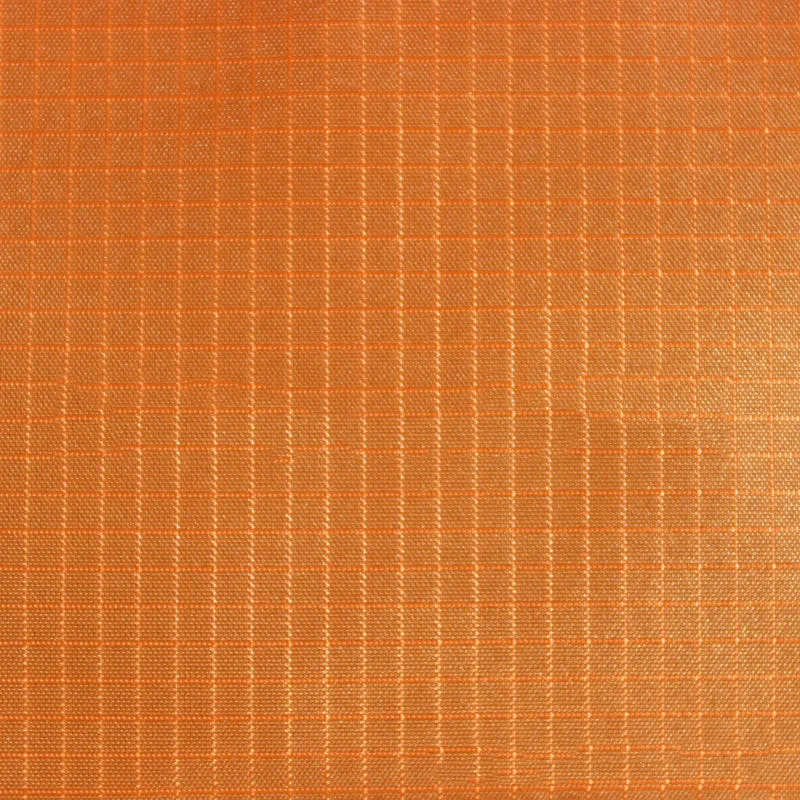

gabardine fabric

Introduction

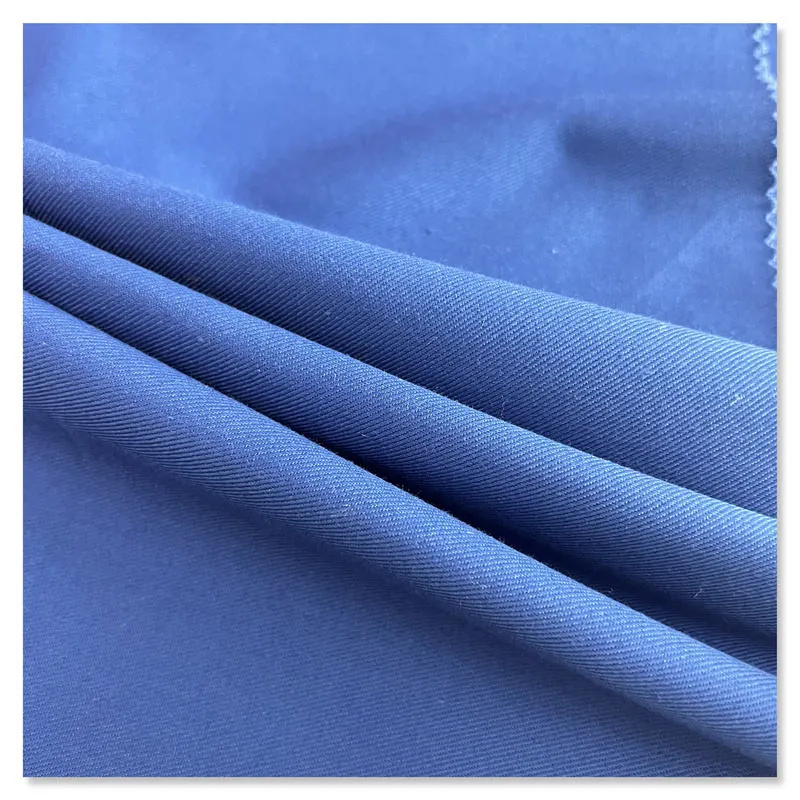

Gabardine is a tight twill wool fabric woven with combed wool yarn and has a certain degree of water resistance. Suitable for raincoats, windbreakers, uniforms and casual wear. There is often twill weave, and the surface of the fabric presents steep twill stripes with an angle of about 63°. It is a right twill weave and weighs 270-320 g/m2. The thin texture is made of twill weave, which is called single-face gabardine, with a weight of 250-290 g/m2. The thick texture is made of satin back weave, called satin back gabardine, thick and fine, with a weight of 330-380 g/m2. The surface of gabardine is flat and smooth, the twill lines are clear and delicate, the hand feels crisp and firm, and the color is soft. Most of them are plain colors, but there are also flash colors and patterns. The warp yarn density is twice that of the weft yarn density, and the warp direction strength is higher, which is firm and durable. However, after wearing it for a long time, the parts that are subject to friction for a long time are likely to form aurora due to the flattening of the lines. Cotton gabardine is made of cotton yarn and is woven in the style of wool gabardine. It has two types: full warp and weft and thread warp and weft. The gray cloth must be finished by mercerizing and dyeing. In addition, there are woolen warp cotton weft gabardine and all kinds of chemical fiber pure spinning and blending gabardine, whose style characteristics vary with the characteristics of the fiber.

Classification

According to the different materials used in warp and weft, it is divided into yarn gabardine (single yarn for both warp and weft), half-thread gabardine (ply yarn for warp and single yarn for weft), and full-line gabardine (ply yarn for both warp and weft). 2/2 ↗ Organization.

material

The raw materials used in this fabric are pure cotton, cotton viscose, cotton fiber and polyester cotton.

application

This kind of fabric is dyed and used as cloth for men’s and women’s clothing in spring, autumn and winter.