Taslon fabric

Introduction

Taslan is a fabric woven from nylon filament or polyester filament and nylon (polyester) air textured yarn. Also known as taslan. 70D nylon filaments are used for the warp, 160D, 250D, 320D and other nylon air textured yarns are used for the weft, and there are also single weft, double weft (250D×2), and triple weft (160D×3). The fabric weave includes plain weave and plain weave (dobby), 2/2 twill weave. Taslan can also be divided into nylon taslon and polyester taslon. The raw material with one direction of warp and weft is air variable yarn (nylon air variable yarn or polyester air variable yarn).

Type introduction

It is mainly divided into two categories: nylon taslon and polyester taslon series.

Jacquard Taslan:

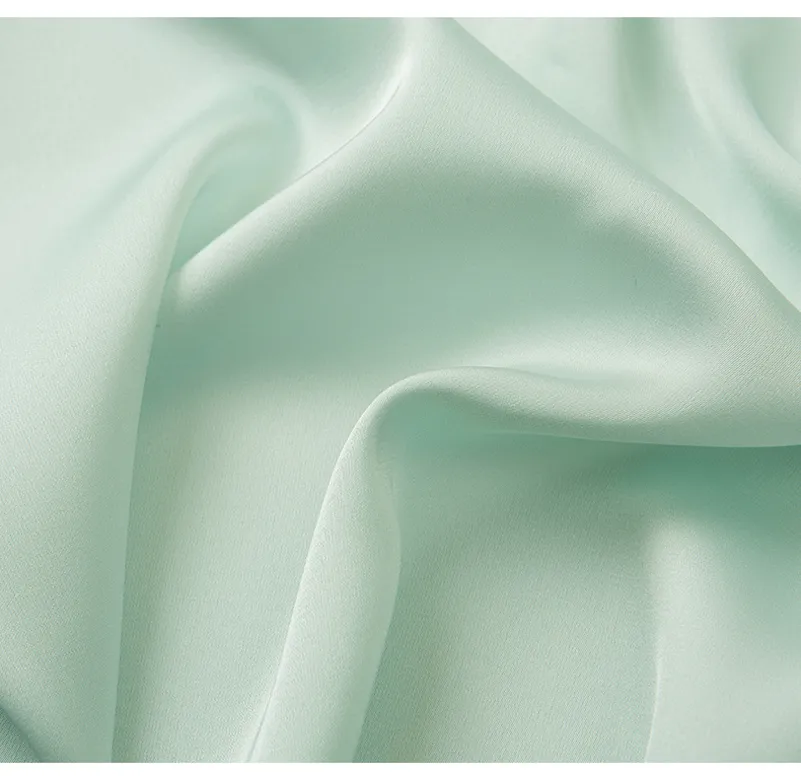

It adopts 70D nylon filament in warp and 160D nylon air variable yarn in weft; the fabric structure adopts double flat jacquard structure and is interwoven on a water jet loom. The fabric not only has the style of jacquard, but also is more creative than the ordinary “taslan” of the same type, and its texture is slightly better. There are varieties of purple red, grass green, light green and other different shades of color. The fabric has the advantages of not easy to fade and wrinkle, strong color fastness, etc. It is suitable for ladies to make casual clothes such as suits and skirts.

Hive Taslan:

The warp of the fabric is made of 70D nylon FDY, and the weft is made of 160D nylon air variable yarn. The warp and weft density is 430X200 threads/10cm. It is interwoven on a water-jet loom with a faucet. The double plain weave is basically used, and the cloth surface forms a honeycomb grid shape. , The gray cloth is first relaxed and refined, alkali-reduced, dyed, and then softened and shaped. The fabric has the characteristics of good air permeability, dry hand feeling, soft and elegant, and comfortable to wear. It can not only be used to make suit skirts, but also can be used as casual wear and children’s wear. The upper body of this kind of fabric is comfortable to wear, elegant in appearance and harmonious in luster. It is a fashionable fabric that people pursue.

Full extinction Taslan:

The warp of the fabric is made of full-dull 70D nylon-6FDY yarn, and the weft is made of full-dull 160D nylon air-variant yarn; the product has a relatively wide range of applications, not only for men’s and women’s sportswear and casual wear, but also for making children’s wear and school uniforms. fabric. The most prominent advantage is that it is more comfortable to wear, has good warmth retention and air permeability, and is loved by consumers. In addition, the product can also use a special coating process to make the hand feel softer and the color more vivid.

Polyester Taslon:

The difference from nylon taslan is only in raw materials, and other weaving and dyeing processes are basically similar.

The main products are:

Glossy polyester Taslan: It is made of polyester big glossy FDY50D and 160D polyester air-change yarn, and the jacquard weave is selected according to the 230T specification, and it is woven on a water jet loom. The cloth width is 150 cm, and each cubic material The cloth weight is about 128 grams. In addition, the printing and dyeing, jacquard and other processes of the back thread make the jacquard pattern rich on the cloth surface, and the fabric feels smooth, suitable for making casual clothes, etc. The finished garment has a sense of fashion and the charm of the times.

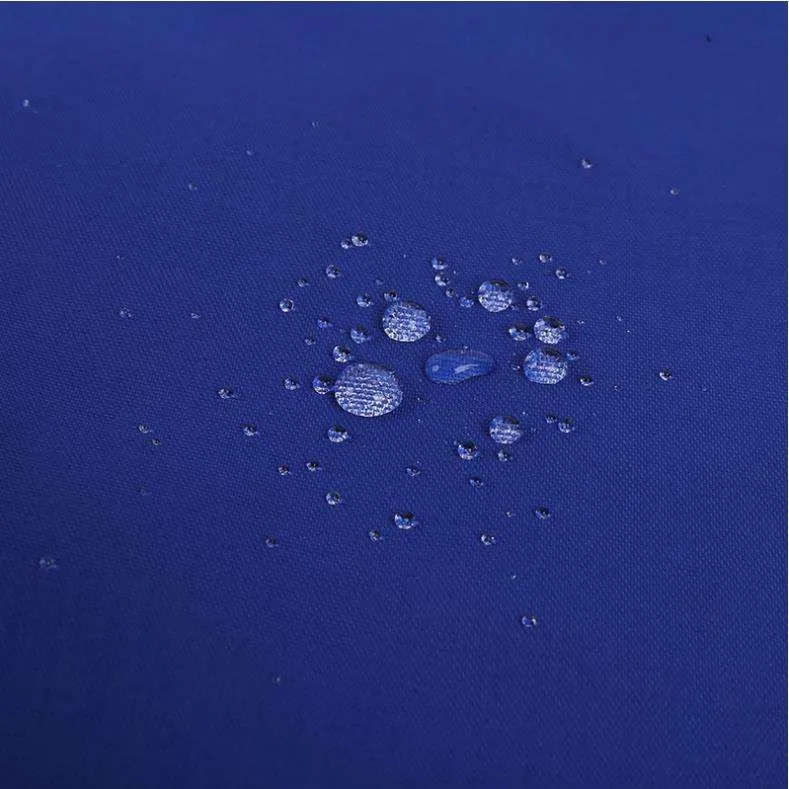

Dull polyester Taslan: The warp of the fabric is full-dull FDY75D, the weft is made of polyester ATY160D, and the fine plain weave is woven on a water-jet loom. The width of the cloth is 160 centimeters, and the weight of each meter of cloth is 85 grams. It has won the long-term trust of customers with its advantages such as soft hand feeling, good waterproof performance and strong wearing performance. In terms of color and luster, the finished fabrics on the market are mainly dark tones, and navy blue, dark coffee and other colors are the most popular. The fabric is suitable for making casual clothes such as jackets and travel clothes. These two taslan fabrics interwoven with polyester, due to the advantages of matching raw materials, make the fabric surface soft and suitable for market demand.